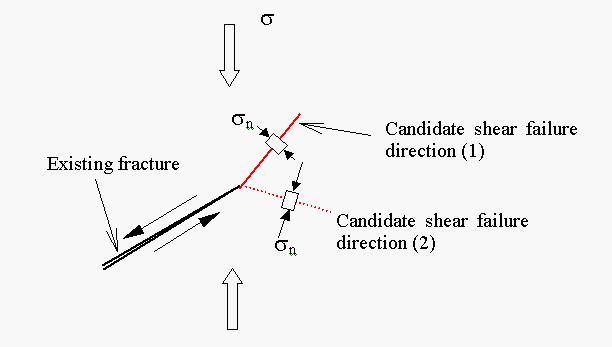

When a fracture propagates in shear at an existing fracture tip, there are always two conjugate candidate propagation directions in which the shear stress reaches the maximum. The same mechanism causes the phenomenon that two conjugate failure planes often occur during triaxial compression tests of rock samples in laboratory. In most cases, however, shear failure takes place only in one direction because the friction resistant is much higher in the conjugate direction due to higher normal stress. Figure A1 shows such a situation, where the candidate direction (1) is the sole fracture propagation direction due to its lower friction resistant than the direction (2).

Figure A1. Two candidate directions of shear failure. Direction (1) is the favourable one due to its low shear resistant.

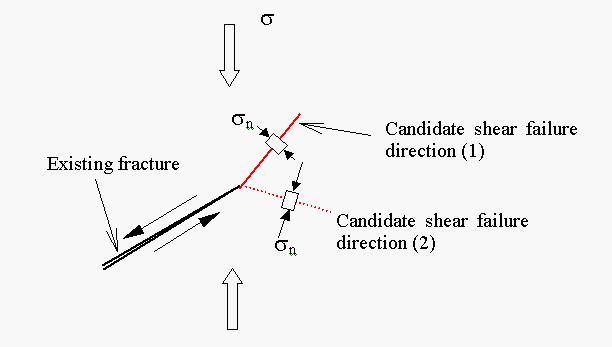

In other cases, shear failure could in theory occur in both directions if the shear resistant happens to be same or similar in the two directions of the maximum shear stress. This is particularly true when the shear failure initiates from an open fracture tip, see Figure A2. In Figure A2, the shear fracture can in theory propagate in both directions (1) and (2) since both directions has the same shear stress and normal stress. In reality, however, a fracture propagation in direction (2) is rarely observed, simply because it creates a conflicting shear movement against the existing fracture. A fracture initiation in direction (2) may occur, but its odd shear direction prevents it from growing longer to form a sustainable shear fracture propagation. In this case the true shear fracture propagation has to be the direction (1) in which the shear movement of the new fracture is consistent with the existing fractures.

Figure A2. Two candidate directions for shear failure. Only in direction (1) can a sustainable fracture growth occur.

To accurately model the shear fracture direction for the cases as shown in Figure A2, we need to ensure that the FRACOD code can intelligently select the physically correct direction (1). This has been done by introducing a criterion to eliminate the shear failure direction which creates conflicting shear movement against the pre-existing fracture. Without such a criterion, the FRACOD code can only randomly select one direction between the two candidate directions, and in some cases gives an incorrect prediction.

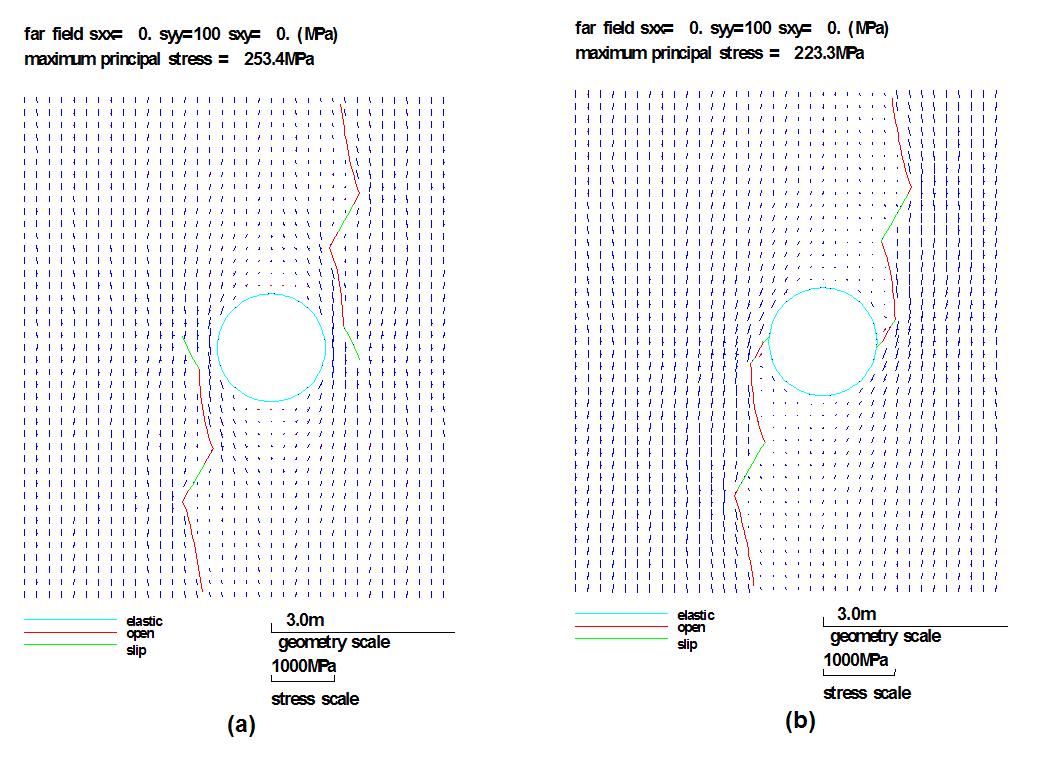

Figure A3 demonstrates the improvement after introducing the direction selection criterion in the FRACOD code. In Figure 3, a borehole and two inclined fractures are modelled to study whether the fractures propagate to the borehole in uniaxial compression. The two figures in Figure 3 show two different paths of fracture propagation predicted by FRACOD before and after the introduction of the criterion. Clearly, the prediction obtained with the direction selection criterion is more reasonable as one would expect such fractures normally propagate to the borehole rather than deviating away from the borehole.

Figure A3. Two fracture propagation paths predicted by FRACOD before (a) and after (b) the shear direction selection criterion was introduced.